A new lab assistant powered by AI and robotics

A new lab assistant powered by AI and robotics

Technological innovation relies heavily on substances devised and refined in chemistry labs. But getting them right can be tedious. Researchers must, for example, mix reagents while varying the formula or the conditions slightly—over and over again.

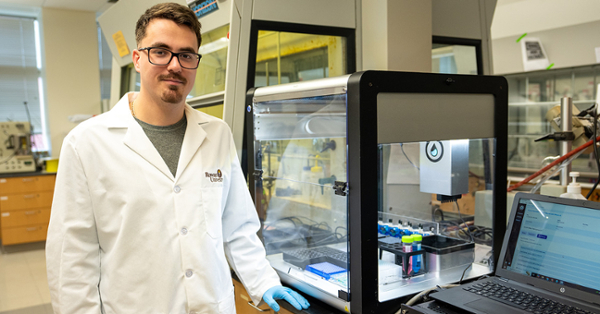

John Schossig, a Ph.D. student in Rowan University’s Department of Physics and Astronomy, and others in Samuel Lofland’s materials science lab are developing an automated system to handle this grunt work.

“It could be a great tool, eliminating the simple tasks and freeing up a researcher to do other, more complex things,” Schossig said. Their system would combine robotics with artificial intelligence (AI) into a unit roughly the size of a mini fridge. They envision it working from a benchtop, where chemists themselves perform experiments.

Leveraging AI and building systems

The system is a work in progress. While the robotics are operational, the team is developing the AI model capable of guiding the robots’ activity.

Schossig and his colleagues are designing it to take over specific tasks as part of a project the lab is undertaking to produce dimethyl carbonate (DMC), a sustainable substance that can function as an electrolyte in batteries. DMC is used as a fuel additive, solvent in paint, and in the production of pharmaceuticals and plastics.

The robotic component of the system will perform parts of this process, including developing a catalyst necessary for an essential step in synthesizing DMC. Once the AI model is complete, it will evaluate the robot’s measurements and decide how to move forward “so a human doesn't have to sit there and say, ‘Okay, this combination of materials looks good, this one doesn’t,’” Schossig said.

Using automation to support chemists

Unlike a human chemist, the system doesn’t need breaks and could potentially perform tasks more quickly, while also eliminating human errors. The time savings could add up, potentially lowering costs and shortening the years or even decades it now takes to get new materials from the lab to market, according to Schossig.

In the long run, he said, the team hopes to develop an affordable approach that could be applied to many different types of repetitive tasks in materials science and other fields. He emphasizes that the goal isn’t to replace human scientists but to assist them.

Lofland, a professor in and head of the department, foresees a clear division of labor between human scientists and automated systems like this one. While the robots can generate a nearly limitless number of samples and measurements, it will be up to humans to make sense of the science behind them, he said.

“These studies are done by specialists in the field and are difficult, time-consuming, and often expensive,” Lofland said. “The data from the robot allows us to make informed decisions about how best to use limited human and financial resources.”