New Rowan lab is super-powered to advance manufacturing through artificial intelligence

New Rowan lab is super-powered to advance manufacturing through artificial intelligence

The rapid development of artificial intelligence and the usability of large language models have promised to transform industries on a large scale, but first engineers must figure out how to integrate intelligent systems with real-world manufacturing methods.

To accomplish that goal, Rowan University’s Digital Engineering Hub (DEHub) is merging smart technology with advanced manufacturing methods through its well-equipped lab launched this fall.

Housed at Henry M. Rowan College of Engineering’s Rowan Hall and directed by Antonios Kontsos, Ph.D., the DEHub lab is capable of digitizing real-world objects, as well as creating new objects based on human- or machine-engineered designs.

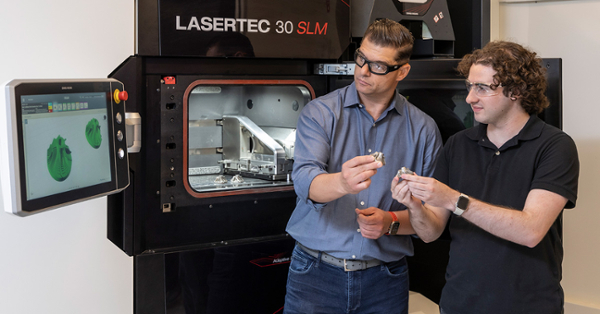

The lab features 3D polymer and metal printers, 3D scanners for digitizing existing objects, and devices for mechanical sensing and testing. DEHub’s key piece of equipment is DMG MORI’s LASERTEC 30 SLM US, the first metal additive manufacturing equipment of its kind.

Designed and assembled in the United States, the 3D metal printer uses a high-powered laser to melt and fuse thin layers of metal powder to create a solid component. The machine’s distinguishing features include its adaptive beam control, improved production process and interconnectivity, allowing the detection—and correction—of flaws in real time during the construction process.

The lab’s processing power is fueled by a highly secure computer cluster named Pythia, after the Oracle of Delphi in ancient Greece. Purpose-built to drive the lab’s systems, Pythia can receive and process terabytes of information instantly.

“We are the first academic research group in the world to connect a supercomputer for this type of machine,” said Kontsos, the Henry M. Rowan Foundation Endowed Professor in the Department of Mechanical Engineering. “The data we’re collecting—such as part temperature and laser information—is in the order of terabytes, so we need the computational power coupled with live -streaming capabilities to synchronously store and process this information.”

Focused first on federally funded research for the Defense Advanced Research Projects Agency, DEHub aims to work across a wide range of manufacturing sectors, including the defense, manufacturing, pharmaceutical, biotechnology, energy and civil infrastructure as well as robotics industries.

Interest is already high. DEHub’s recent launch event attracted representatives from companies as far away as California, Texas and even Australia.

“Our horizon is not to improve the Glassboro economy only,” Kontsos said, “We want to improve it by being a resource worldwide.”

About DMG MORI

DMG MORI is a leading global manufacturer of high-precision machine tools and is represented in 44 countries – with 124 sales and service locations, including 17 production plants. In the “Global One Company,” more than 13,500 employees are driving the development of holistic solutions in the manufacturing industry. Under the guiding principle of Machining Transformation (MX), DMG MORI combines four pillars for the efficient, sustainable production of the future: Process Integration, Automation, Digital Transformation (DX) and Green Transformation (GX).

DMG MORI stands for innovation, quality and precision. Our portfolio covers sustainable manufacturing solutions based on the technologies Turning, Milling, Grinding, Boring as well as Ultrasonic, Lasertec and Additive Manufacturing. With technology integration, end-to-end automation and digitization solutions we make it possible to increase productivity and resource efficiency at the same time.

At our production sites worldwide, we implement holistic turnkey solutions for the main sectors of aviation & space, automotive & e-mobility, die & mold, medical and semiconductor. With the DMG MORI Qualified Products (DMQP) partner program, we offer perfectly matched peripheral products from a single source. Our customer-oriented services cover the entire life cycle of a machine tool – including training, repair, maintenance and spare parts service.

About Rowan University

Since its founding in 1923, Rowan University has evolved from a teacher preparation college to a public research institution ranked among the top 100 in the nation by U.S. News & World Report. Rowan University offers bachelor’s through doctoral degrees and professional certificates in person and online to nearly 25,000 students through its main campus in Glassboro and its eight other locations in southern New Jersey.

Rowan focuses on practical research at the intersection of health care, engineering, science and business, while ensuring excellence in undergraduate education. The University has earned national recognition for innovation; commitment to high-quality, affordable education; and the development of public-private partnerships. A Carnegie-classified R2 (high research activity) institution, Rowan is the fastest-growing public research university in the Northeast and among the nation’s top 10 fastest-growing, as reported by The Chronicle of Higher Education. In 2025, Rowan opened New Jersey’s only veterinary school and is one of only two universities in the nation to offer M.D. , D.O. and D.V.M. medical degrees.