NSF CAREER Award: Crystal formation studies could improve production methods

NSF CAREER Award: Crystal formation studies could improve production methods

Industrial crystallization is a widespread process that plays a critical role in the production of bulk and fine chemicals, food products, pharmaceuticals and several materials. The manufacturing process for those products often generates unwanted impurities that can incorporate into the final crystallized product, leading to a change in its properties or to adverse health effects.

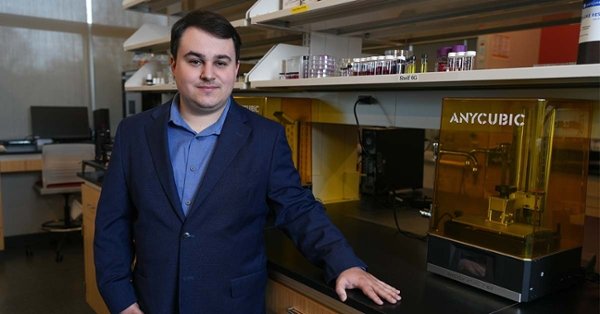

With support from a five-year, $574,000 National Science Foundation (NSF) Faculty Early Career Development (CAREER) Award, Gerard Capellades, Ph.D., an assistant professor of chemical engineering in the Henry M. Rowan College of Engineering, will investigate the mechanisms by which impurities incorporate in growing crystals. His research will center on the behavior of those impurities as they are drawn from the surrounding liquid into the crystal’s surface.

Understanding how impurities are retained in a product during the crystallization process could point the way toward better production methods for novel materials. In pharmaceuticals, the work could lead to improved medications and potentially fewer side effects for patients.

“I saw it as a challenge and an opportunity at the same time,” Capellades said.

The NSF CAREER program offers the federal agency’s most prestigious awards in support of early-career faculty serving as academic role models in research and education. Faculty honored with the award are recognized for their potential as outstanding leaders in their field of research.

To closely study the crystallization process in the lab, Capellades will use readily available compounds, such as acetaminophen (the active ingredient in Tylenol) and salicylic acid (a precursor to aspirin), which produce crystals with well-characterized shapes. Capellades will use dyes as model impurities to test the research methods and validate their findings with relevant industrial impurities.

“Once we figure out why impurities prefer certain regions of the crystal, and how that preference changes with processing conditions, we may find a way to reject them,” Capellades explained. “The same information can also be used to find out how to get a desired additive inside the crystal. That could lead to new pharmaceuticals that combine different compounds with synergistic medical effects or to new materials for applications beyond pharmaceutical work.”

One of the research phases will use a Mach-Zehnder interferometer—a device using lasers, mirrors and a camera—to precisely measure the structure of the liquid that surrounds the growing crystal, essentially creating a map of its contents. The resulting data will reveal how fast those unwanted substances attach to the developing crystal and how that attachment is affected by the crystallization conditions.

The project will involve several studies and research opportunities for undergraduate and graduate students. Moreover, Capellades will offer crystallization workshops for hundreds of middle and high school students, using chocolate to introduce them to the fields of crystallization and chemical engineering.