Under pressure, these foams get even stronger

Under pressure, these foams get even stronger

Polymeric foams are the unsung heroes in products like sports helmets and other protective gear, absorbing the impact of collisions to keep users safe. Rowan University, in collaboration with San Diego State University, has been awarded a $278,068 grant from the National Science Foundation to study a new kind of protective material—auxetic foams.

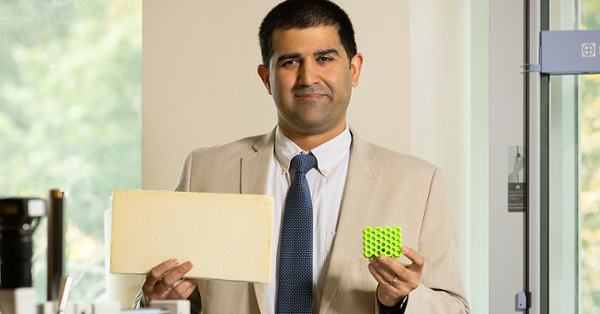

Led by Dr. Behrad Koohbor, an assistant professor of mechanical engineering in the Henry M. Rowan College of Engineering, the project aims to examine the foams on a microscopic level to learn about their properties and determine how to manufacture auxetic foams for commercial use.

Auxetic foams are unique in that they become stronger as force is applied. Compared to materials, like bamboo, that break under pressure, auxetic foams “actually push back,” Koohbor said. “They tend to become stronger as you deform them.”

As a part of the research, Koohbor and his team will manipulate the physical properties—like weight and strength—of the foam by changing the structure of the material on various scales, from a micrometer level to a centimeter length scale. This will impact the way the foam behaves overall when it’s used in a helmet or the sole of a shoe, for example. Because auxetic foams are so new, this research will help scientists better understand how these materials react upon impact.

“By carefully studying the microstructure of the foam and correlating that with the larger scale properties, we hope to be able to use that information to further improve the mechanical load-bearing and impact energy mitigation capacities of the foams,” Koohbor said.

Koohbor has already studied auxetic foams in shoe soles with promising results. He found that auxetic foam is more effective at absorbing energy than soles with traditional foam.

“You get good mechanical strength and improved cushioning behavior at much lighter weight,” Koohbor said.

Researchers at San Diego State University will create the auxetic foams in various shapes and sizes and send them to Rowan for examination. Then the teams will discuss the results and determine what changes in the chemical makeup of the foam are necessary to produce even stronger samples of auxetic foams.

Koohbor and his team are analyzing the first samples of auxetic foams sent from San Diego State University.

Koohbor is assisted by two graduate students, several undergraduate students, and an incoming doctoral student for the spring semester. Kazi Zahir Uddin, a graduate research fellow working with Koohbor, is excited to work on cutting-edge research.

“Rowan is one of the best places to do this kind of research,” Uddin said.

Koohbor hopes this research will be the first of many examinations into this new class of foams, which, hopefully will be used in commercial products in the future.

“We are very excited to work with our chemist and materials scientist collaborators to really make this new class of foams applicable and available to many different fields, especially in sports and protective padding applications,” Koohbor said.