Rowan engineers are developing a method to strengthen fibers—with lasers

Rowan engineers are developing a method to strengthen fibers—with lasers

Fibers are used in virtually every industry — from aerospace to athletics, energy to health care. So scientists have long worked to develop stronger, better fibers. Rowan researchers will now take these efforts to the next level, working to create the strongest polymer fibers to ever exist.

“Our inspiration is to engineer materials that are the highest performance that anyone can create,” says Rowan University’s Vince Beachley, Ph.D., the project's leader.

Moreover, Beachley and his team aim to create techniques that can be used on a large scale — enabling companies to manufacture these ‘super fibers’ for an array of applications that benefit society.

That could be anything from better bike helmets to longer-lasting batteries to improved medical devices, says Beachley, associate professor and graduate coordinator in the Henry M. Rowan College of Engineering’s Biomedical Engineering Department.

The fibers would be incorporated in various ways, often as membrane-thin sheets in devices and fibers embedded in composites to create strong structural materials.

Beachley and his team recently received a $523,000 grant from the National Science Foundation to research and refine their methods over the next three years. The grant will also support students' involvement in the research, including two Rowan Ph.D. candidates, 10 undergraduates, and a community college student underrepresented in science and engineering. The students will be paid or receive course credit, as well as mentoring and other support.

“This project offers advanced training in materials science, manufacturing and nanotechnology to numerous students,” notes Beachley. “And it creates a unique pathway for a deserving community college student to enter a bachelor's program in engineering.”

The team will be the first to develop a systematic understanding of how certain fibers are affected and strengthened by various levels of heat, temperature, and force used for stretching. They will conduct extensive experiments and create mathematical models.

“Dr. Beachley is a pioneer in this area and well positioned to impact the fundamental engineering of nanofiber systems and also enable and create new technologies,” says Dr. Mark Byrne, professor and founding head of the Department of Biomedical Engineering. “It is a testament to the strong engineering research we have at Rowan.”

An ‘aha’ moment — with lasers

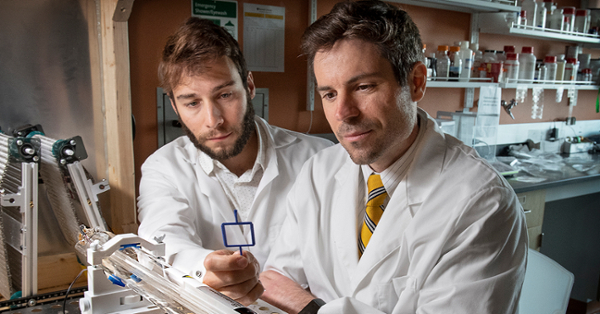

Doctoral student Matthew Flamini has already played a key role in this initiative since joining Beachley's lab three years ago. In fact, the graduate research assistant came up with a novel way to heat the project’s ultra-thin nanofibers, which are about 1/200th the width of a human hair.

“Matt is the one who proposed using lasers to heat the fibers,” Beachley recalls. “He assembled a laser heating apparatus and collected the preliminary data” needed for the research grant.

The laser beam’s heat makes the nanofibers pliable so they can be stretched, which causes their molecules to align in a chain. The fibers must then be cooled quickly so the molecules lock into place, strengthening the barely visible strands. The researchers hypothesize that nanofibers can be made stronger than thicker fibers, due to their high ratio of surface area to volume, which enables faster heating and cooling.

Prior research on nanofibers has used heating elements or solvents to soften them. However, the laser's precision enables the researchers to quickly scan the beam over each fiber, sequentially heating and cooling a millimeter or so at a time, reducing the chances of breakage.

A manufacturing innovation

The research will also use another promising technology: a track system that Beachley pioneered and refined over the past decade.

This automated device — which looks a bit like a loom — holds, moves, and stretches each fiber as the laser heats the strands, section by section.

“The track system is what makes this scalable,” explains Beachley. “We can run thousands of fibers per minute with a single laser source.”

Many types of fibers can be engineered, including nylon, polyester, polyethylene, and carbon. Flamini is especially excited to work on a biodegradable poly(lactic acid) (PLA) fiber approved by the Food and Drug Administration for biomedical uses.

By enhancing PLA nanofibers, for example, “we could make them last longer inside the body” and fine-tune their abilities to absorb and release medications, Flamini suggests.

The researchers believe this work will lay vital foundations for future applications no one has imagined.

“We think the sky's the limit,” says Beachley.