Rowan researchers find cost-effective method to cut greenhouse gas

Rowan researchers find cost-effective method to cut greenhouse gas

With rising sea levels, record-high global temperatures, and changing weather patterns, scientists are searching for creative—and inexpensive—ways to battle climate change.

Rowan University researchers and their partners at Sekisui Chemical have figured out how to efficiently convert a greenhouse gas into useful materials that can be sold to make new products like plastics.

What’s more, their new, cost-effective process can be powered by renewable energy sources. The result is a sustainable, affordable production method that’s actually good for the environment.

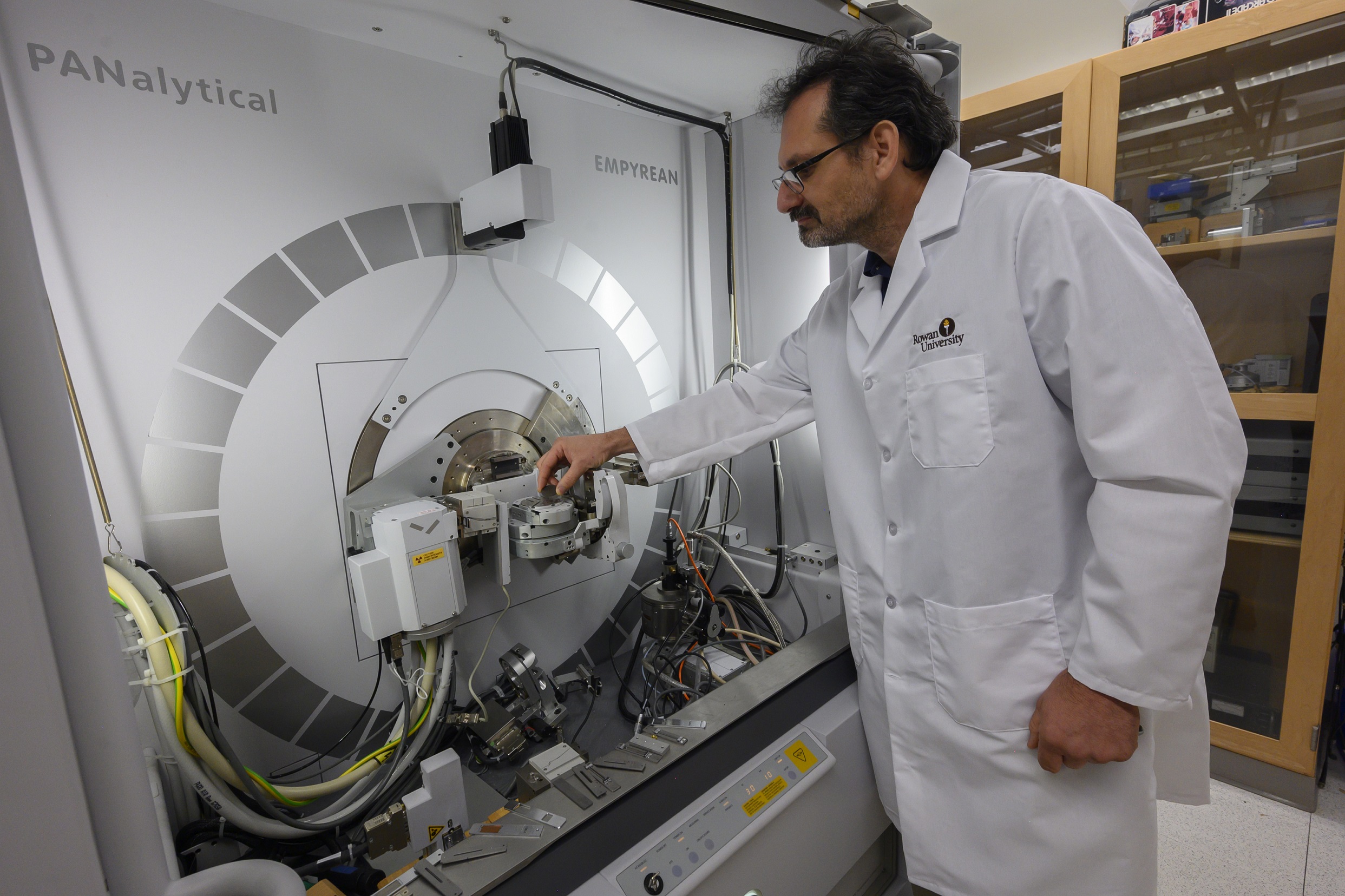

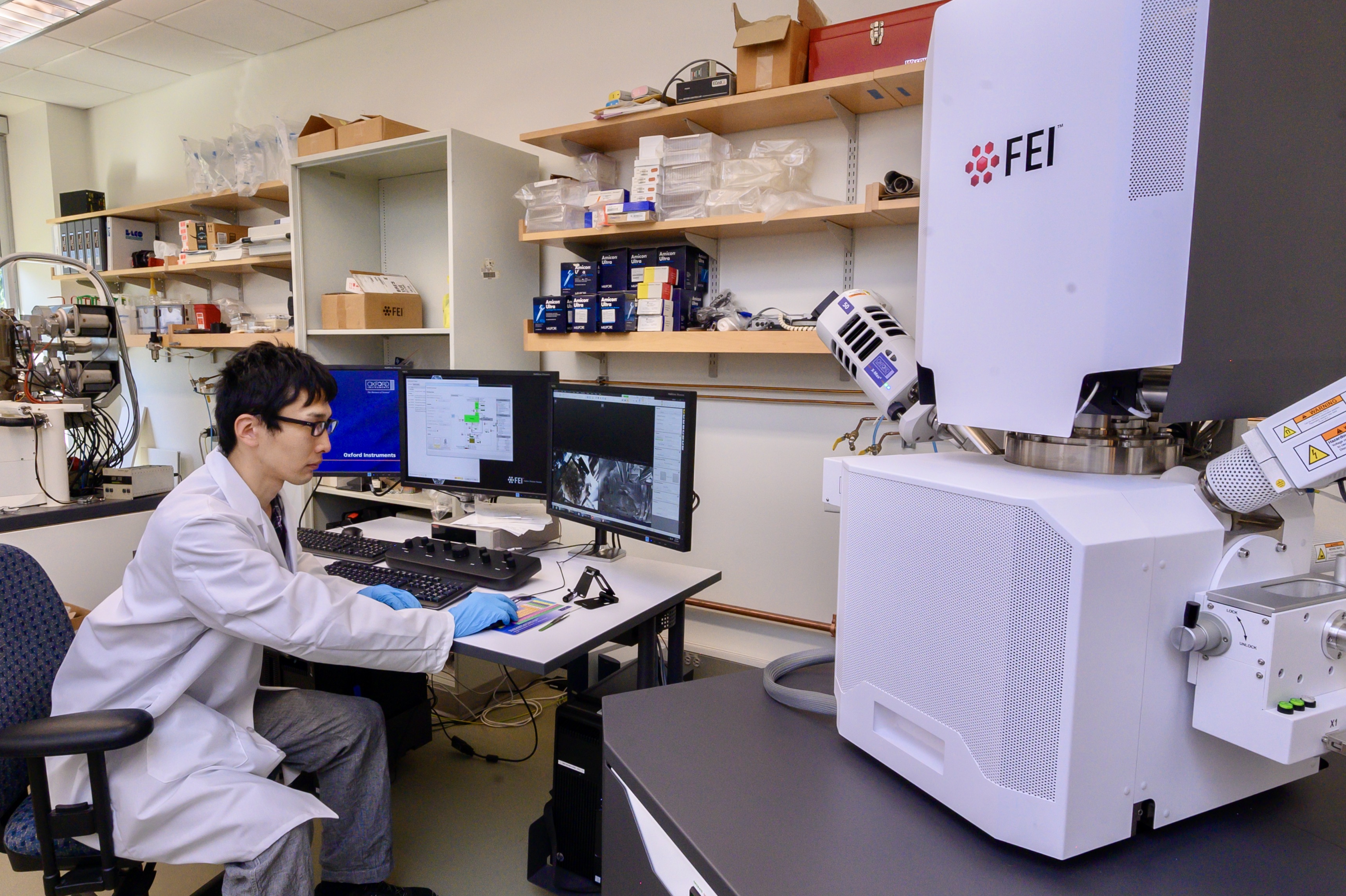

Developed by Dr. Samuel Lofland, a Rowan physicist; Atsushi Ikoma, a researcher at Sekisui Chemical, and Naohiro Fujinuma, a graduate student in the Henry M. Rowan College of Engineering, the new method centers on a novel electrochemical catalyst to reduce atmospheric carbon dioxide, the primary greenhouse gas produced in massive quantities by human activities such as through burning fossil fuels.

The researchers recently described their new method of electrochemical catalysis in Advanced Energy Materials, a leading, peer-reviewed scientific journal focused on energy issues.

“We will keep seeking an appropriate application of this technique to maximize its market value and accelerate sustainable advancement,” said Ikoma.

Simply put, “electrochemical catalysis is a means of transforming carbon dioxide into other useful compounds,” explained Lofland, a professor in the Department of Physics & Astronomy in the College of Science & Mathematics.

Electrochemical carbon dioxide reduction is known to be a clean method of reducing global carbon emissions and converting carbon dioxide into fuels and raw materials when used with a renewable energy source. Until now, however, it has been too inefficient to be cost-effective for implementation.

The new catalyst is made from inexpensive, readily available materials using a simple, straightforward method that is easily configurable to large-scale, commercial, and industrial applications.

“Our particular catalyst has demonstrated not only high throughput for this reaction but more importantly, high energy efficiency and durability—two factors which are key to the commercialization of this technology,” said Lofland, who also co-directs the Advanced Materials & Manufacturing Institute at Rowan University, a research institute focused on advancing fundamental and applied science and engineering technology.

“Our progress is very encouraging,” said Fujinuma, a graduate student in the Materials Science & Engineering (MSE) Ph.D. program, an interdisciplinary program of chemistry, physics and engineering. Applying the technology on an industrial level in large electrochemical plants powered by renewable energy sources, he said, would be an effective strategy to reduce humans’ carbon footprint.

“One can imagine solar or wind farms that supply electricity to electrochemical plants so that no carbon dioxide is created as a byproduct during the process,” said Lofland. In turn, these plants “will extract the predominant greenhouse gas in the atmosphere while simultaneously producing raw materials for plastics and thereby lessening the need for fossil fuels, which are the typical feedstock,” said Lofland.

Their research benefited from Fujinuma’s chemistry background in catalysis and green energy, and Lofland’s experience in the physics of nanomaterials and composites.

“The success of our collaboration comes from the synergy of our expertise,” said Lofland. “Overlapping, but distinctly different perspectives allowed us to learn from each other and greatly expedited our progress as we developed ideas and techniques that were not based upon our training in either physics or chemistry but rather combinations thereof.”

“I am excited to show the strong progress of our collaboration on electrochemical carbon dioxide conversion, which I believe to be one of the most promising techniques for creating a sustainable carbon cycle,” said Fujinuma.

Together, the researchers plan to continue developing novel catalysts to produce specific organic compounds for commercial use. Their efforts are being expedited by advanced data analysis through machine learning methods.