Getting (Virtually) Real

Getting (Virtually) Real

As caves go, they're not usually this high-tech. Caves are ancient structures, right? They're cold, damp, and, often as not, full of bats.

Not so with Rowan's CAVE®. This 10' x 10' x 10' enclosure, housed on the first floor of the South Jersey Technology Park, is about as high-tech as it gets.

The Cave Automated Virtual Environment is an interactive, fully immersive device where Rowan engineering faculty and students, through the power of virtual reality, test rocket engines for NASA, troubleshoot on-board systems for U.S. Navy ships half a world away, even plumb city sewer networks for flood and drainage issues.

Since its arrival this spring, the CAVE® has enabled Rowan students to acquire real world experience through technology beyond anything they might ordinarily hope for as undergrads.

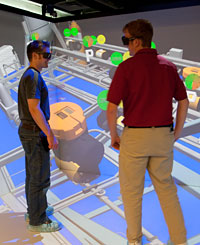

Donning special virtual reality goggles, students working in the CAVE® enter a space not unlike that in the Matrix, the futuristic sci-fi movie. It is a computer generated, three-dimensional environment designed for space-age problem solving.

"We're using programs many working engineers don't have access

to and I'm just halfway through college," said Sophomore Cliff

Kaelin, 20, of Malaga.

"What's amazing is here you have undergraduate students working

with cutting edge technology and being exposed to projects outside

traditional engineering environments," said Dr. Shreekanth

Mandayam, professor and chair of Electrical and Computer

Engineering. "It makes our students very marketable."

Rowan purchased the CAVE® - the only such unit at any college or university in New Jersey - with a $392,000 grant from the National Science Foundation. NASA provided roughly $250,000 in funding for project support and the Navy awarded $100,000 to support the work.

Dr. Mandayam, who spent a 2005 sabbatical at NASA's Stennis Space Center in Mississippi through a National Academies Fellowship, said work performed at Rowan's CAVE® complements other research, particularly with regard to NASA engine testing and monitoring ship-board systems.

"Simulations can save millions of dollars," he said. "Every rocket engine test costs NASA several hundred thousand dollars. Running a test in software, once you've developed a model, is practically free."

Just as important, he said, is the terrestrial work he and his students are involved with.

"Rather than moving earth, cutting metal and doing physical tests, we do it all through VR," Dr. Mandayam said. "With VR you can address building infrastructure, protein synthesis, engine design, flood control, city planning. The list goes on and on."

Watch a video of the CAVE® on YouTube >>>